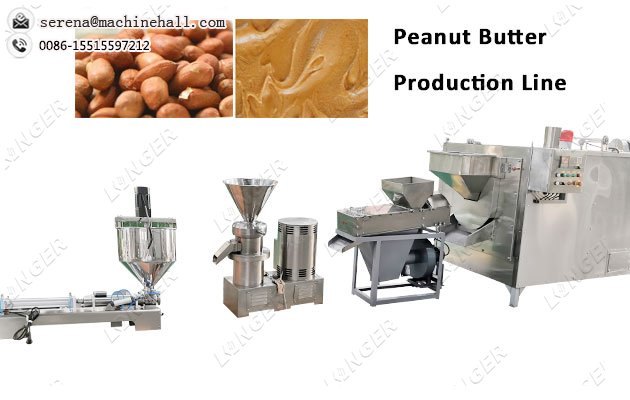

This is a set of fully

automatic hazelnut butter production line, which can complete the roasting, grinding, mixing, filling of hazelnut paste. The output is 500kg/h, realizing continuous production. Suitable for large and medium-sized hazelnut processing plants.

Hazelnut Paste Production Process:

Hazelnuts → cleaning → roasting → cooling → peeling → grinding sauce → stirring → cooling → vacuum degassing → packaging

Main Equipment of Hazelnut Paste Production Line

(1) Roasting machine: continuous roasting of hazelnuts, high efficiency and energy saving, uniform roasting and pure taste. The hazelnut roaster is divided into two types: electric heating and gas heating, with fast temperature increase and stable performance.

(2) Cooling belt: Use the principle of a fan to extract hot air to cool the roasted hazelnuts.

(3) Peeling machine: peel the roasted hazelnuts. During the peeling process, the hazelnut kernels and skins are automatically separated.

(4) Hazelnut Butter Grinding Machine: The coarsely ground peanuts are further ground, and the processing fineness is further improved.

(5) Stirring: Make the hazelnut paste more uniform.

(6) Cooler: Cool the ground hazelnut paste to a temperature suitable for filling.

(7) Degassing tank: Degas the hazelnut paste before filling.

(8) Filling: Fill the finished hazelnut paste into a bottle or bag.

Advantages of the Hazelnut Butter Production Line:

-

High degree of automation, greatly saving manpower.

-

Bake at constant temperature to ensure flavor. Ensure the high quality of hazelnut paste.

-

High efficiency and output, suitable for large and medium-sized hazelnut paste factories.

-

Support customization, and the entire line can be designed according to the customer's plant.