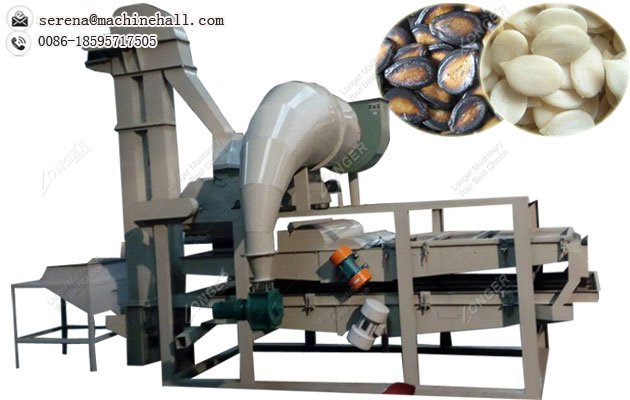

Watermelon Seed Peeling Machine Introduction:

This unit is mainly composed of a hopper, the raw material hoist, the multifunctional impurity removing machine, the bucket elevator, the double shelling machine, check the machine (3 sets), the receiving hopper, the wind back to the feeding system, to centralized control cabinet.

Watermelon seed sheller is a patented product of LONGER Machinery Co., Ltd., which is the best equipment in the world. The equipment is used for shelling, peeling, separating rice seeds, removing the kernel and returning to the hulling machine for shelling again and continuously. Watermelon skin, powder, watermelon seeds from each outlet excluded. The machine has the characteristics of high automation, continuous processing, high rice yield and good skin removal effect.

Features of Egusi Shelling Machine:

1. A wet shelling method is adopted

2. Through the improvement of the original hulling machine, the shell efficiency is higher and the crack rate of nut is lower.

3. The application of the circulating unshell, i.e. the unshelled kernels automatically enter the next shell cycle;

4. In the collection and treatment of leather, it adopts vibration negative pressure separation to replace the blowing method and reduces the production of dust.

5. The selection screen and the size of the sieve are added to make the kernel adequately sift and reduce the fragmentation caused by the return of the kernels.

6. At the same time, we can process different sizes of white gourd seeds by changing the sorting sieve section.

7. The structure is compact, low dissipation and easy operation and maintenance.